Description

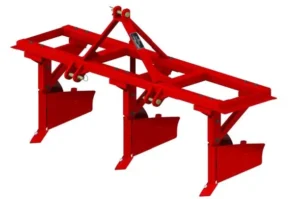

PANTHER 3 Rows Potato Planter

Welcome to India Watanabe Soil Stabilizer Co., Ltd., your certified India Manufacturer and premier specialist in high-capacity, robust Potato Planter Machine equipment. The PANTHER 3 Rows Potato Planter is engineered for industrial-scale commercial operations where maximum uptime, material capacity, and multi-row efficiency are paramount. Weighing a formidable 1500 Kg and featuring ultra-large bunkers (750 Kg Seeds and 600 Kg Fertilizer), the PANTHER drastically extends continuous field operation. Utilizing a minimum power input of 100 cv, this 3-in-1 integrated planter guarantees superior depth consistency and synchronized application across three rows, ensuring foundational plant health and optimal yields across India’s major potato-growing regions.

PANTHER 3 Rows Potato Planter Technical Specifications:

The PANTHER 3 Rows is engineered for high-volume, continuous field operation and extreme stability.

| Specification | Value (PANTHER 3 ROWS) | Unit | Significance in India |

| Model | PANTHER 3 ROWS | – | Industrial Scale: Built for high-volume, multi-row planting. |

| Empty Weight | 1500 | Kg | Super Heavy-Duty: Provides critical structural stability and depth force. |

| Min. Engine Power | 100 | cv (HP) | High HP Required: Ensures stable operation across 3 rows with full load. |

| Number Rows | 3 | – | Precision coverage for three rows. |

| Seed Bunker Capacity | 750 | Kg | Max Capacity: Significantly reduces refill time. |

| Fertilizer Capacity | 600 | Kg | Max Capacity: Integrated basal application for long runs. |

| Tank Insecticide (Option) | 300 | L | Essential for large-scale pest protection. |

| Working Speed | 3-5 | km/h | Accuracy: Optimal speed for consistent spacing and smooth operation. |

| Linkage Category | 2 | – | Standard robust connection. |

Structural Integrity: Heavy-Duty Planting for Commercial Scale

The PANTHER 3 Rows Potato Planter is defined by its massive weight and structural rigidity, directly addressing the complexities of large-scale, high-input planting.

Max Capacity Bunkers: 750 Kg Seeds and 600 Kg Fertilizer

The combined 1350 Kg capacity (750 Kg Seeds / 600 Kg Fertilizer) is designed for maximum logistics efficiency. This volume allows the machine to cover immense distances, enabling operators to plant for an entire shift or longer without returning for material resupply.

-

Uptime Maximization: This feature is crucial for contract planters, translating directly into maximized field uptime and revenue during the short planting season.

-

Reduced Logistics Costs: Fewer trips to the headland minimize fuel and vehicle wear, reducing the overall operational Potato Planter Machine Price in India per hectare.

H3: Power-to-Row Ratio: 100 cv for 3 Rows Precision

The 100 cv minimum power requirement is necessary to smoothly and consistently pull the heavy 1500 Kg machine, fully loaded with 1350 Kg of material, while simultaneously engaging three sets of planting shoes and openers. This power ensures:

-

Consistent Depth: The machine cuts through surface resistance evenly across all three rows.

-

Synchronized Feed: Maintains accurate seed spacing at the target 3-5 km/h speed, critical for synchronized emergence.

Integrated 3-in-1 System with Extreme Structural Rigidity

The 1500 Kg Empty Weight of the PANTHER provides superior structural stability for the 3 Rows operation. This extreme mass dampens ground undulations and lateral pull (especially on uneven terrain), ensuring the machine maintains a near-perfect depth and alignment. This structural rigidity is foundational for the integrated 3-in-1 success: placing the seed, fertilizer, and protective agent in the perfect, synchronized position.

The Commercial Imperative: Scale and Uptime

The PANTHER is the solution for commercial operators who manage their profits by minimizing non-productive time and maximizing multi-row throughput.

Optimizing Labour and Logistics Economics

By enabling extended periods of continuous planting, the PANTHER reduces the dependency on a large, complex logistics chain. Fewer resupply cycles mean fewer workers dedicated to material transport and handling, allowing the farm to allocate labor efficiently to other tasks, ultimately reducing overhead.

Tackling Hard Soil and Complex Terrain

The sheer mass of 1500 Kg and the robust chassis provide the necessary penetration force to plant into challenging seedbeds, including compacted rows or fields with heavy clay content (common in regions like Telangana). This prevents the planting shoes from riding up and ensures the critical planting depth is maintained across all three rows, which is vital for crop consistency.

Quality Assurance for Tuber Consistency

The PANTHER’s design directly supports maximum tuber quality. The highly accurate and stable planting across 3 Rows promotes uniform size distribution, which is essential for meeting the stringent quality and grading requirements of major food processors and export buyers.

Live Experience: Quantified Field Performance

We provide quantifiable data and verified customer reports demonstrating the superior capacity and field efficiency of the PANTHER.

Customer Story 1: Maximizing Continuous Field Time in Uttar Pradesh

A major commercial seed potato grower in Uttar Pradesh needed to minimize operational interruptions. They transitioned from older 2-row models (which required refills every 3 hours) to the PANTHER 3 Rows Potato Planter.

The Solution: They focused on maximizing the uptime by utilizing the full 750 Kg Seed and 600 Kg Fertilizer bunkers.

The Result: The PANTHER achieved an average continuous field run time of 8 hours before requiring resupply, covering approximately 25 acres per shift. This dramatic extension of continuous field time resulted in a 55% reduction in logistical field traffic and maximized the use of their 100 cv tractors during the daylight hours.

Customer Story 2: Stability and Depth Consistency in Hilly Maharashtra

A large farmer in a hilly region of Maharashtra required consistent depth on sloped fields where light planters often drifted.

The Solution: They relied on the 1500 Kg Empty Weight of the PANTHER to provide penetration stability, utilizing a 110 cv tractor.

The Result: The added structural mass effectively dampened lateral drift and maintained a near-perfect planting depth across uneven terrain, resulting in a 12% tighter emergence window across all three rows compared to previous equipment. The robust frame and linkages experienced zero unscheduled maintenance issues over the season, confirming the superior durability promised by the India Manufacturer.

Corporate Profile: The India Watanabe Advantage

Your Trusted India Manufacturer for Soil Machinery

India Watanabe Soil Stabilizer Co., Ltd. is a certified India Manufacturer and the dedicated regional subsidiary of the globally recognized Watanabe group. Our core mission is to provide high-efficiency, durable machinery—from precision tools like the PANTHER 3 Rows Potato Planter to heavy-duty equipment like the THOR Stone Crusher—that directly addresses the unique challenges posed by India’s diverse soil types, monsoon conditions, and rapid infrastructure expansion. We are committed to mechanical simplicity, longevity, and superior local support.

A Legacy of Engineering Excellence, Rooted in Gujarat

Our operational headquarters and dedicated manufacturing base are strategically located in Ahmedabad (Gandhinagar Region), Gujarat. This central location provides us with a strategic advantage, enabling us to efficiently manage logistics and provide rapid, responsive technical support and spares availability across major agricultural states. Our adherence to rigorous manufacturing quality standards ensures that every piece of machinery provides predictable, sustained performance and the industry’s lowest long-term running costs.

Expert Knowledge Hub (FAQ & Technical Deep Dive):

Frequently Asked Questions (FAQ) about the PANTHER 3 Rows Potato Planter

-

Q: What is the minimum horsepower (HP) required for the PANTHER 3 Rows?

-

A: The machine requires a minimum engine power of 100 cv (HP). This increased requirement is necessary to smoothly pull the heavy 1500 Kg machine, fully loaded with 1350 Kg of material, while planting across three rows at the optimal speed.

-

-

Q: What is the total combined material capacity?

-

A: The PANTHER 3 Rows has a total combined capacity of 1350 Kg (750 Kg seeds + 600 Kg fertilizer), designed for minimal stops and maximum field throughput.

-

-

Q: Can the optional 300 L insecticide tank be fitted later?

-

A: Yes. The machine chassis is pre-designed and reinforced to support the weight and linkage of the optional 300 L tank system, allowing for flexible upgrading to the full 3-in-1 functionality.

-

-

Q: How does the heavy weight impact planting in lighter soil?

-

A: The 1500 Kg weight is carefully distributed. While heavy, it provides consistent downforce essential for achieving uniform planting depth, which is vital regardless of soil type, preventing the planter from bouncing or riding up on light soil.

-

The Physics of Synchronization: Achieving Perfect Seed-Fertilizer Alignment

The PANTHER’s internal mechanism ensures that the seed drop, fertilizer placement, and protective chemical application are precisely synchronized relative to each other. This critical synchronization, coupled with the stability of the 1500 Kg frame, minimizes field passes and maximizes the utility of the large 600 Kg fertilizer bunker, leading to superior crop emergence across all three rows.

Complementary Potato Production Solutions

For a fully mechanized potato production system, integrate the PANTHER with essential complementary equipment.

Soil Preparation and Row Management

-

Potato Furrower (R-380/R-580 Series): The PANTHER is typically preceded by a Potato Furrower to create the initial clean, deep furrow base.

-

Rotary Cultivator (ERA-3100 Series): Use a Rotary Cultivator first for optimal soil aeration and residue breakup, ensuring a fine seedbed that maximizes the planter’s accuracy.

-

Stone Crusher (THOR Series) / Rock Picker (CT-2100): Pre-clearing fields with stone management equipment protects the planter’s delicate shoes and ensures consistent planting depth and spacing.

Post-Planting and Harvest

-

Potato Diggers (AWB-1600 Series): High-quality planting leads directly to a uniform crop, maximizing the final recovery rate and efficiency of the Potato Diggers during harvest.

Ready to Optimize Your Farm? Contact India Watanabe

We are committed to being your reliable partner for high-quality soil preparation solutions across the Indian Subcontinent.v

| Information Category | Detail |

| India Manufacturer | India Watanabe Soil Stabilizer Co., Ltd. |

| Address Line 1 | Plot No. 405, GIDC Industrial Estate |

| Address Line 2 | Near Phase III Check Post, Vithalapur Road |

| City, State, PIN | Ahmedabad (Gandhinagar Region), Gujarat, 382150 |

| Country | India |

| Technical Support | [email protected] |

Instant Quote Option

To ensure buyers receive accurate pricing: Get Final Price Quotation

Reviews

There are no reviews yet.