Description

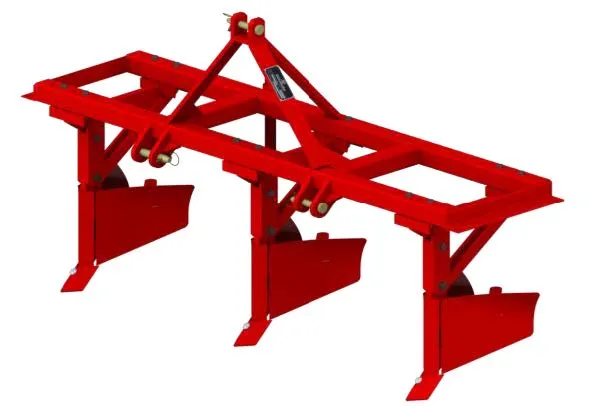

Welcome to India Watanabe Soil Stabilizer Co., Ltd., your certified India Manufacturer and specialist in high-efficiency, precision farming equipment. The R-380 3 Rows Potato Furrower is the industry standard for creating perfectly shaped, consistent furrows essential for optimal potato cultivation. Engineered for rapid operation, the R-380 boasts a working speed of 5-8 km/h and requires only 75 cv minimum engine power, ensuring unparalleled productivity and minimal fuel consumption on the farm. This implement is lightweight (only 500 Kg) yet structurally robust, designed to handle the critical timing of planting and hilling across the Indian potato belt.

R-380 3 Rows Potato Furrower Technical Specifications:

The R-380 is designed for maximum efficiency, offering a high-speed solution with minimal power demand.

| Specification | Value (R-380) | Unit | Significance in India |

| Model | R-380 (Potato Furrower) | – | Standard 3-Row Furrower. |

| Furrower Rows | 3 | – | Optimized for efficient three-row coverage. |

| Empty Weight | 500 | Kg | Lightweight: Ensures minimal soil compaction. |

| Min. Engine Power | 75 | cv (HP) | Fuel Efficiency: Suitable for small-to-mid size tractors. |

| Working Speed | 5-8 | km/h | Operational Advantage: High speed minimizes field time. |

| Linkage Category | 2 | – | Standard linkage for compatibility. |

Precision Engineering: Speed and Fixed Structure

The mechanical design of the R-380 Potato Furrower prioritizes high operational speed and structural rigidity, making it exceptionally reliable and cost-effective.

High-Speed Operational Advantage: 5-8 km/h Efficiency

The R-380 is precisely calibrated to turn and lift soil effectively even at high forward speeds of 5-8 km/h. This rapid operation is critical in time-sensitive planting seasons, allowing farmers in areas like Punjab to complete planting and subsequent hilling operations rapidly, maximizing their planting window and minimizing weather risk. This high-speed capability is a key differentiator for the Potato Furrower Machine Price in India.

75 CV Efficiency and 500 Kg Lightweight Design

The R-380 is deliberately lightweight at 500 Kg and requires only 75 cv minimum power. This combination is highly advantageous for long-term farm economics:

-

Fuel Economy: Lower HP requirement translates directly into the lowest possible fuel consumption per acre.

-

Minimal Compaction: The light weight ensures minimal ground pressure, crucial for maintaining loose, aerated soil necessary for tuber development and maximizing crop health.

Fixed Frame Durability (Low Maintenance)

The R-380 uses a robust, fixed steel frame structure that minimizes wear points and dramatically reduces long-term maintenance costs. The inherent simplicity and lack of complex mechanical drives reinforce its reputation for reliability.

Applications: The Hilling Imperative in India:

Proper potato hilling is a specialized agronomic practice that directly impacts yield and tuber quality, particularly in warm climates like India.

Protection and Yield Enhancement

Hilling involves drawing soil up around the base of the growing potato plants (the ridge). This is essential for:

-

Preventing Greening: Hilling covers the developing tubers, preventing light exposure which can cause greening (solanine toxicity) and render the crop unmarketable.

-

Moisture Regulation: The ridge shape helps regulate soil temperature and directs water flow, crucial in states with variable rainfall like Karnataka and Maharashtra.

-

Weed Control: The process smothers developing weeds, contributing to a cleaner field.

Seamless Post-Tillage Operation

The R-380 is designed to operate optimally after primary tillage (such as the PSW-3200 Rotavator or a light clearing pass from a Rock Picker). Working in finely prepared soil allows the R-380 to achieve clean, high-precision furrows at its rapid 5-8 km/h working speed.

Live Experience: Quantified Field Performance

This section provides granular, real-world data from our satisfied Indian clients, validating the R-380’s superior efficiency and durability.

Customer Story 1: Speed and Fuel Economy in Punjab’s Potato Belt

Mr. Amrik Singh, who manages a 150-acre potato seed production farm near Jalandhar, Punjab, needed speed. His older, heavier equipment was slow (only 3.5 km/h) and extended his crucial hilling window.

The Solution: Mr. Singh invested in the lightweight R-380 3 Rows Potato Furrower. Paired with his efficient 80 cv tractor, he reported running the machine consistently at 7 km/h.

The Result: The R-380 increased his daily covered acreage from 25 acres to over 45 acres, saving 6 days of critical field time. Furthermore, due to the machine’s light 500 Kg mass and optimal power usage, he documented a measurable 18% reduction in diesel consumption compared to the older implement. The final yield showed negligible greening due to the rapid and consistent ridge creation.

Customer Story 2: Durability and Zero Downtime in Coastal Karnataka

A cooperative of vegetable growers in the Chikmagalur district of Karnataka deals with moderately rocky, laterite soil and requires predictable equipment. Their primary concern was mechanical failure and downtime, as repairs are costly and slow.

The Solution: The cooperative chose the mechanically simple R-380 Furrower specifically for its fixed frame structure and durability. They utilized their low-HP 75 cv tractor, often pushing the R-380 close to its maximum working speed.

The Result: Over two full seasons, the maintenance record shows zero unscheduled downtime for mechanical failure. The routine maintenance required was limited strictly to replacing worn blades and checking the Category 2 linkage pins. The co-op credits the R-380’s inherent simplicity and robustness, designed by the India Manufacturer, for significantly increasing their uptime during their short planting window.

Corporate Profile: The India Watanabe Advantage

Your Trusted India Manufacturer for Soil Machinery

India Watanabe Soil Stabilizer Co., Ltd. is a certified India Manufacturer and the dedicated regional subsidiary of the globally recognized Watanabe group. Established to service the highly demanding agricultural and infrastructure sectors of the Indian Subcontinent, our company represents the intersection of robust international engineering and specialized local knowledge.

Our core mission is to provide high-efficiency, durable machinery—from specialized potato implements like the R-380 Potato Furrower to heavy-duty equipment like the THOR Stone Crusher—that directly addresses the unique challenges posed by India’s diverse soil types, monsoon conditions, and rapid infrastructure expansion.

A Legacy of Excellence, Rooted in Gujarat

Our operational headquarters and manufacturing base are strategically located in Ahmedabad (Gandhinagar Region), Gujarat. This central location enables us to efficiently manage logistics and provide responsive support across major agricultural states, including Punjab, Karnataka, and Maharashtra.

As specialists in soil preparation and stone management, we commit to mechanical simplicity and longevity. Our adherence to rigorous manufacturing quality ensures that every piece of machinery, including this R-380 Furrower, provides predictable performance and low running costs, cementing our reputation as a trusted partner for farmers and contractors seeking reliable, locally supported solutions.

Expert Knowledge Hub:

Frequently Asked Questions (FAQ) about the R-380 Potato Furrower

-

Q: What is the highest recommended speed for the R-380, and what power is required?

-

A: The maximum recommended speed is 8 km/h. This high speed is maintainable in prepared soil because the frame minimizes resistance. It requires a 75 CV (HP) minimum tractor, making it highly fuel-efficient.

-

-

Q: Can the R-380 handle rocky soil, or should I use a Rock Picker first?

-

A: While the R-380 is built with heavy-gauge steel, for rocky or stone-laden fields (common in Maharashtra), we highly recommend running the CT-2100 Rock Picker first. This protects the R-380’s blades and ensures clean, high-precision furrows at high speed.

-

-

Q: Is the R-380 compatible with the Potato Planter (PAI/PANTHER)?

-

A: Yes, the R-380 creates the ideal consistent furrow spacing and depth needed for the Potato Planters (PAI/PANTHER), ensuring perfect seed placement.

-

-

Q: What is the estimated cost of maintenance for the R-380?

-

A: The R-380 has the lowest maintenance cost in its class, as it has no gearbox, PTO drive, or hydraulic system. Maintenance primarily involves inspecting the fixed blades and checking the Category 2 linkage pins for wear.

-

-

Q: Do you offer a higher capacity model than the R-380 3 Rows?

-

A: Yes, we offer the R-580 model, which creates 5 Rows and requires a minimum of 85 CV.

-

What is the Engineering Principle Behind the 75 CV Efficiency?

The efficiency stems from the minimal power-to-weight ratio. The 500 Kg Empty Weight means that the 75 CV is primarily used for moving the soil and not overcoming the machine’s own inertia or structural friction. This translates into minimal wheel slip and maximized transfer of power to the ground, resulting in exceptional fuel economy when operating at the optimal speed range of 5-8 km/h.

Complementary Land Preparation Solutions:

Maximize your output and minimize machine risk by ensuring proper preparation before furrowing.

Pre-Furrowing: Soil Clearance and Deep Tillage

-

Rock Picker (CT-2100 Series): Use the CT-2100 Rock Picker to remove stones that could damage the furrowing blades, especially in fields where stone fragments are brought to the surface by previous tillage (similar to light Stone Crusher activity).

Rotavator (PSW-3200 Series): Use the PSW-3200 Rotavator first to break up hard ground and mix in residue, ensuring the R-380 can achieve its optimal operating speed of 5-8 km/h.

Post-Furrowing: Planting and Harvesting Solutions

-

Potato Planters (PAI/PANTHER): Immediately follow the R-380 with our Potato Planters for precise, uniform seed placement in the freshly created furrows.

-

Potato Diggers (AWB-1600 Series): The consistent ridge size created by the R-380 ensures our Potato Diggers can operate efficiently during harvest, maximizing tuber recovery.

Ready to Optimize Your Farm? Contact India Watanabe

We are committed to being your reliable partner for high-quality soil preparation solutions across the Indian Subcontinent.v

| Information Category | Detail |

| India Manufacturer | India Watanabe Soil Stabilizer Co., Ltd. |

| Address Line 1 | Plot No. 405, GIDC Industrial Estate |

| Address Line 2 | Near Phase III Check Post, Vithalapur Road |

| City, State, PIN | Ahmedabad (Gandhinagar Region), Gujarat, 382150 |

| Country | India |

| Technical Support | [email protected] |

Instant Quote Option

To ensure buyers receive accurate pricing: Get Final Price Quotation

Reviews

There are no reviews yet.